Our children will, or already have asked: What did we do to stop fossil fuel companies from driving the planet to extinction? Here are some of my answers.

(If you are of the mind that this is not happening, then I will suggest to you that the powerful disinformation networks have you convinced of something that is not true. Here is a page with my own simple description of anthropogenic climate change: )

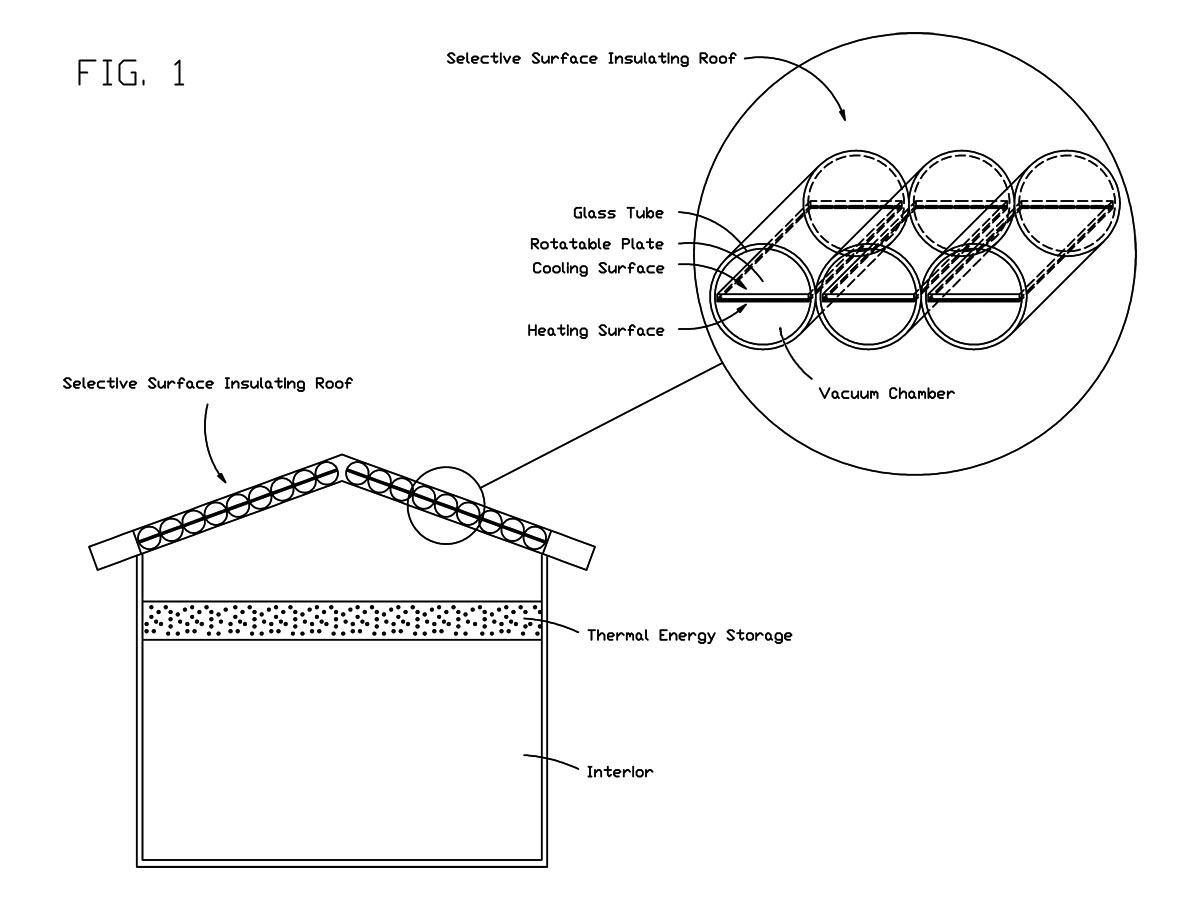

Free Heating and Cooling Radiant Insulating Roof: (Dec 1, 2020)

Disclosed is a new type of roof. It does what no roof has ever done, which is to have a net beneficial heat transfer for both Summer and Winter. This roof comprises glass tiles containing vacuum chambers. In the chambers are rotatable plates that rotate selective surfaces to face the sky. One is for heating, and one is for cooling. Heat energy is positively moved across the roof radiantly, while the vacuum insulates to minimize conductive loss. The radiant gain outweighs the conductive loss for a net positive heat energy flow. Of course, this is a simplification. follow the following link for a better description.

Radiant Roof

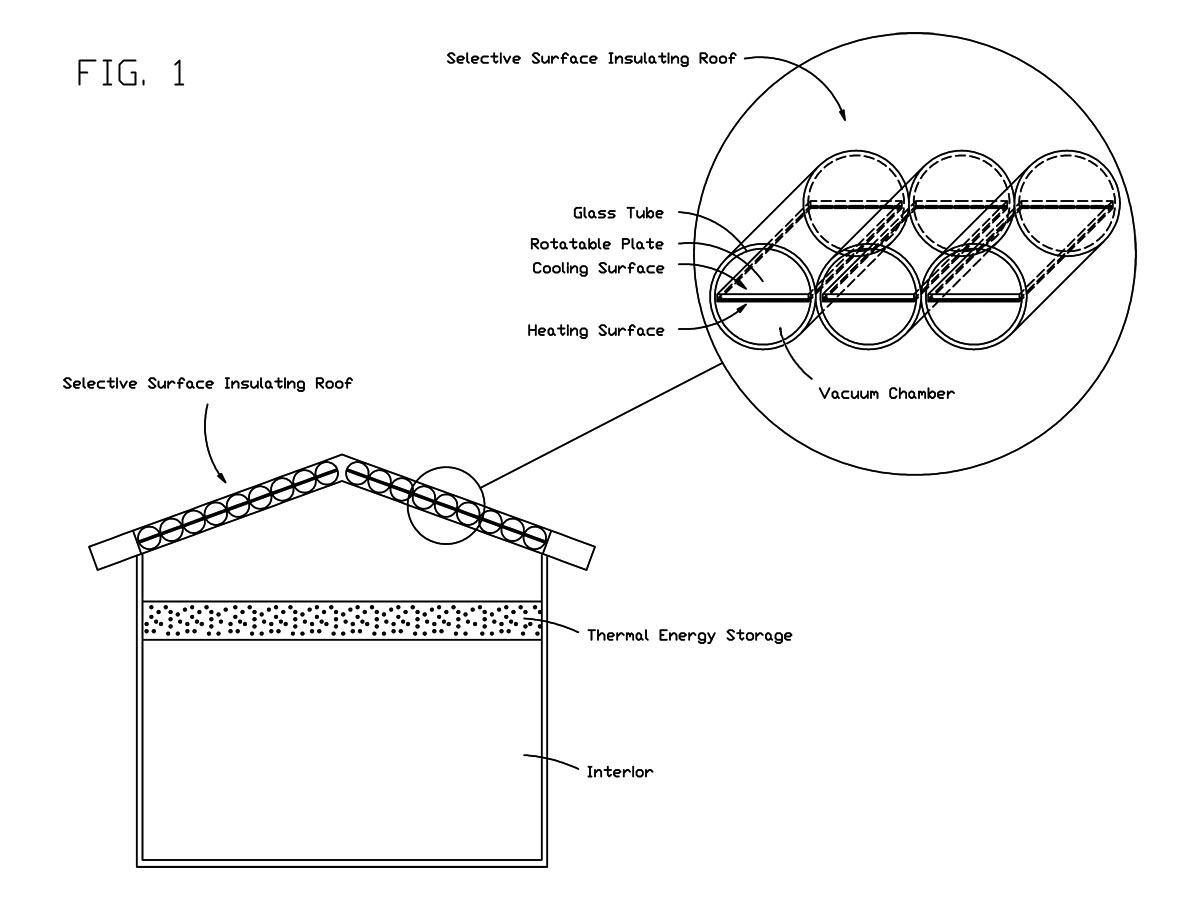

Combined HRV and Heat Pump utilizing novel air cyle: (May 16, 2022)

Disclosed is a new combined heat recovery ventilator (HRV) and heat pump (HP).

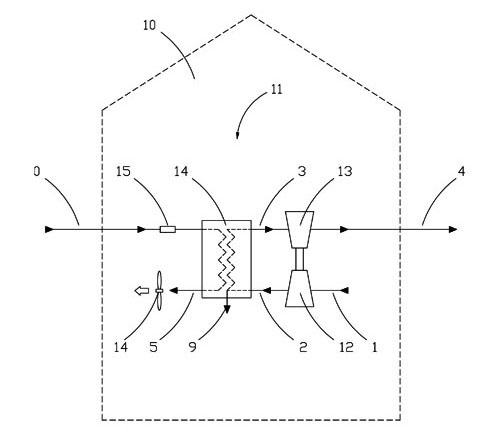

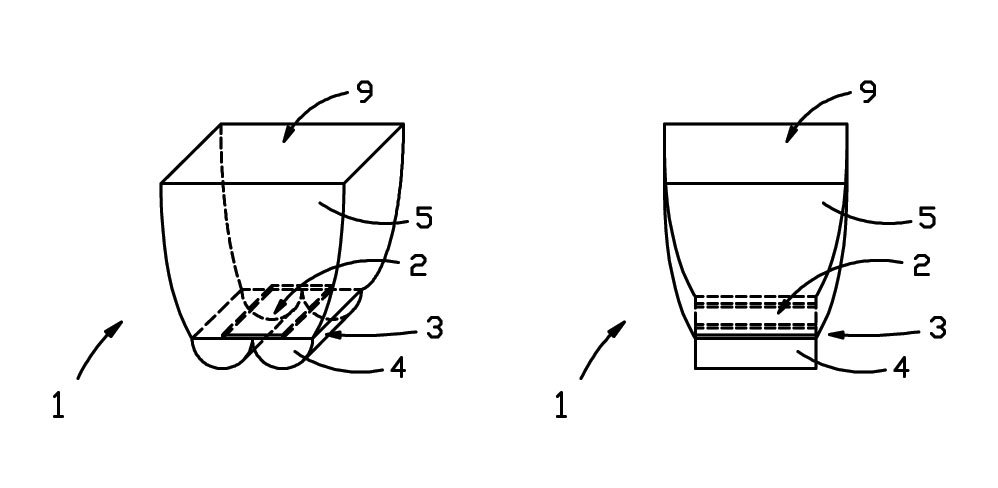

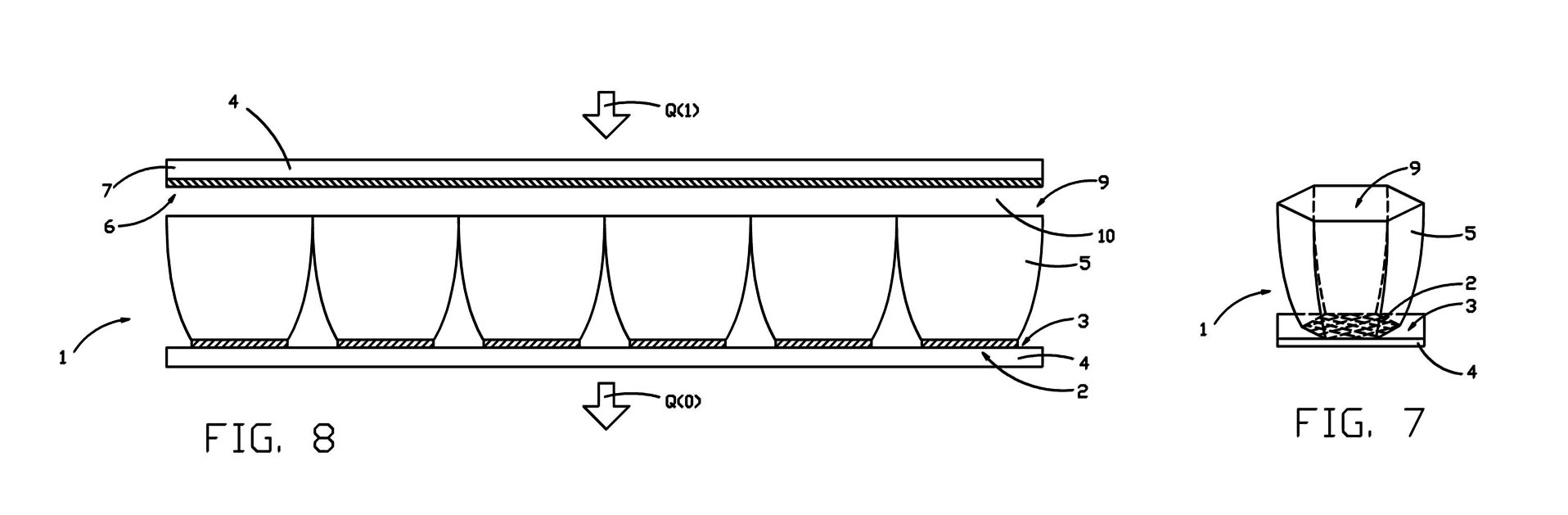

Disclosed are new types of concentrators. Some of these concentrators can concentrate radiant energy, such as solar energy from a full hemispheric view of the sky to a PV cell that is one quarter of the size of a traditional PV cell. The advantage is to reduce the cost of the most expensive part of a solar PV panel.

Fig. 2 illustrates a cross-section of a revolved embodiment to give a general idea of what these concentrators look like. Fig. 3 illustrates a cross-section of another revolved embodiment.

Fig. 2  Fig. 3

Fig. 3

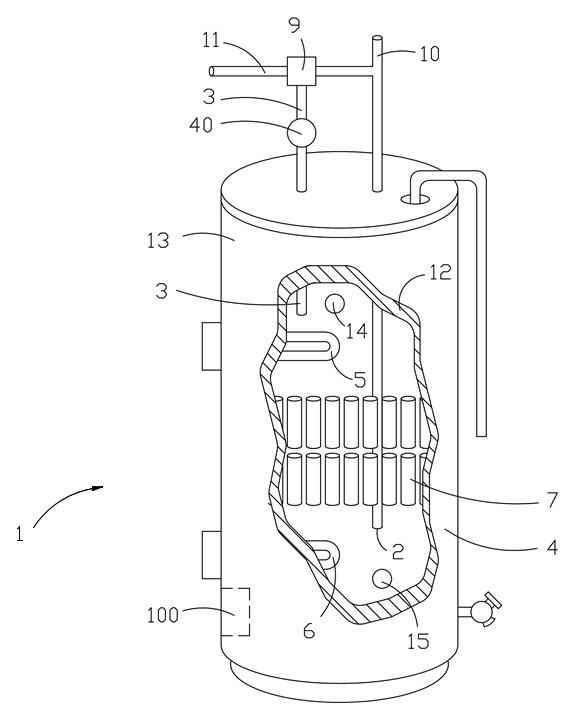

Grid Interactive Water Heater (GIWH) with Heat Pump and PCM based TES

Water heaters are significant contributers to climate change. All domestic water heaters need to be replaced with these:

Grid Interactive Water Heater w/ TES and PCM

This is what will replace our home heaters and A/C:

(The basic concept here is to use the cool of night to cool during the day in Summer, and to use the relative warmth of day to heat during the Winter. Put another way, a heat pump's performance can be significantly improved by changing the temerature gradient in which it runs through utilizing the daily temperature cycle.)

Thermal Energy Storage for HVAC

Much safer cars:

(If you are young, cars are your highest death threat. This design significantly reduces forces for all passengers.)

Solar Desalination: (Posted 6/16/2020 & 7/19/2020)

Desalination is generally done for us. Salt water sources are almost always large, and the Sun extracts pure water from salt water and deposits it in the atmosphere as humidity. However, it is not easy to extract it from the air, or directly from a saline source. Included in this next link are two ideas for using PV to power methods to extract water both from the source, and from humid air.

Move heat energy with no external energy input:

Selective Surfaces for Radiative Heat Transfer

Electrical Energy Storage, including Pumped Hydro-based Electrical Storage: (Posted 7/19/2020)

The following link has several electrical energy storage ideas.

JP 6115867 Multidirectional Button

US 10,275,153 B2 Multidirectional button, key, and keyboard

US 20/190,196,711 A1 Multidirectional button, key, and keyboard

US 10,095,316 B2 Scrolling and zooming of a portable device display with device motion

US 9,696,809 B2 Scrolling and zooming of a portable device display with device motion

Also, there are other non-listed applications pending.

These generally disclose methods of overcoming the fundamental limitations of small devices, like smartwatches, which are inherently less addictive. Unfortunately, these are solutions to problems that the tech industry doesn't want solved.

FOLDING SMART DEVICES: Included in one of my patent applications is a folding smartphone device which comprises non-bendable screens. Multiple screens fold and then slide together to form one screen. This is still an open patent.

ROCKER SKIS: Some years ago, I was at a demo day for ski shop employees. The K2 rep (John Lyons) said to me:

Will, nobody knows it yet, but we just signed Shane McConkey. So, I'm asking everyone if you have skied the Spatula (Volant Spatula). If so, did you like it? Should we make it?

I said: Yes, I've skied it. It works great in deep powder. But it is terrible getting out a traverse line to get to the powder. (The Spatula was shaped like a water ski.) With the reverse sidecut, it turns downhill when you put it on edge. You have to do all this stepping around to get out a traverse line. When you back on the groomed to get back to the lift, you have to sit back on the tails and slide them around. If you are centered and hit a bump, you just roll forward (- as it has reverse camber along with reverse sidecut.)

What you guys should try is to make a ski that has normal sidecut and camber under the center of the ski. But leave a big tapered tip and tail.

Next season, K2 released the Pontoon, which mostly matches that description. (I suspect the Burton Fish snowboard may have also played a roll in the tapered design.)

I ran across John out cycling after the ski came out and reminded him of the conversation. He either didn't want to confirm that - still working for K2, or he didn't exactly remember our conversation. But what he said was:

I headed up to Vashon Island (home of K2) right after the demo day. A bunch of us threw out ideas for Shane's signature ski. The engineers made up a bunch for him to try, and the ones he liked became the Pontoon.

Lots of skis copied that ski. It was the first "Rocker" ski. Although, the term came later, and I have no idea who coined it.

Powder magazine stated: "At the time, McConkey was both surprised and impressed: “I would have built something completely different,” he said in the 2007 edition of K2’s SKEEZE Magazine. “I’m glad they didn’t listen to me, because the Pontoon is 10 times better than the Spatula ever was.” (https://www.powder.com/stories/classics/the-catalyst/)

So, I know where the basic idea came from. And that's the story of the Rocker ski. Shane is credited with it, and that is just fine by me. I saw him a few times, but only really knew his Mother, who used to come out the local ski races. This experience, as well as others, is partly why I post these ideas. Ideas spread. And sometimes they spread with compound growth rates. At some point, they hopefully reach the right person that has the right skills and opportunity to take the next steps. I hope some of these ideas will spread that way.

NARROW WIDE CHAINRINGS AND PULLEYS: I invented the narrow wide chainring and pulley idea that is part of what it took for Sram to make the first 1X drivetrain. This style of drivetrain has taken over mountain biking. I showed them the idea at least a decade ago, and applied for a patent (US Appl 08/667076). Unfortunately, I didn't understand then that I could claim a new use, as the USPTO returned that the idea had originally been done on farm equipment. Oh well! BTW, Avid's arch supreme brake was an idea I gave them too.

HELIOX TRANSPORTATION: Back around 2006, I took part in the Human Powered Vehicle Challenge for UNR. I suggested not doing it, and instead trying set a cycling record by cycling around an enclosed loop filled with heliox. Heliox is a gas that is 20% oxygen and 80% helium, so it is much lighter that air. Basically, it just replaces the nitrogen in air with lighter helium.

I gave up on that idea when I saw how much helium costs, and basically it wouldn't really prove much. It is obvious that a transportation vehicle would move more efficiently through lighter heliox than air. I am not sure who all I communicated this idea to. It was discussed at the HPV competition at Moffett Field. It seems to have made it to Larry Page who started an internal project at Google. Here is a link:

I have also suggested this idea to Hyperloop. It would not be near as efficient as a vacuum, but it wouldn't kill anyone from lack of a breathable gas, which Hyperloop will if the pressurized vehicles lose their air supply.

PIVOT FOR ORIENTATION CHANGE: Back in the early '80s, I can remember suggesting to a company that I think was called Portrait Displays that they should consider making their monitors pivotable. This was during the 80x25 monochrome DOS era. In those days, a portrait monitor made more sense for word processing (with WordStar, etc). But Landscape made more sense for spreadsheets (Lotus 123, etc). All monitors made you choose, and what was good for one was bad for the other. A year or so later pivoting monitors made their debut. You can trace that all the way to pivoting your smartphone from portrait to landscape for orientation changes. Got to say though, whoever came up with using the accelerometer to determine when to change orientation had a real stroke of genius! So I wonder if I was at the genesis of the idea.

FREE ENGINE IDEAS:

(Prior to 3-5-2020) NOVEL TURBOCHARGED & SUPERCHARGED ENGINE: Turbos give more power, but superchargers give quicker response. Decades ago Lancia combined the two to get the best of both in the '80's Delta Integrale rally car. VW and Volvo now make excellent super turbo engines. But there is a different way to do this, and it has advantages. An engine can be made where one set of cylinders (or rotor) is supercharged with the exhaust connected to a turbocharger. The turbo then pressurizes the intake of the other set of cylinders (or rotor), with its exhaust free flowing.

Now one would think that this arraignment would just deliver a middle-ground blending of characteristics of the two methods of boosting an engine. However, the exhaust that comes out of the supercharged side would ramp up the exhaust energy and pressure quicker than a common turbocharged cylinder would - when the throttle is depressed. More exhaust energy will spin the turbo up quicker, and the engine would then have a response much closer to a supercharged engine than a turbo, or a blend.

Another advantage is that the turbo only needs to be half the size of a conventional turbo engine with a single turbo. Smaller turbos spin up faster. Likewise, the supercharger also only needs to be half the size. And compared to a twin-turbo engine, one supercharger takes the place of one of the turbos and still increases the throttle response further.

A half-turbo and half-supercharged engine, as explained here, is still compatible with other methods of reducing turbo lag. Methods comprise early exhaust valve opening, and slightly delaying the spark when you want to build boost. These methods are complimentary. Further, this type of super-turbo engine can be done with any multicylinder (or multi rotor) engine. Although "V" type engines seem particularly suitable. Also, if the supercharger is a positive displacement pump, then the turbo wastegate can be eliminated, as this arraingment is not a positive feedback loop - and pressures would not get out of control.

The end result would be a really great performance engine. I am giving this idea away, though, as it is not really what is needed to drastically lower carbon emissions.

(Posted 4/19/2020) Another possible method of implementing this design is to not split cylinders, but to have the supercharger routed to one intake valve, and the turbocharger routed to the other intake valve in a cylinder with two intake valves (as is common is four valve engines). This idea would be particularly suited to completely variable valve engines, as further descussed below. Both exhaust valves could lead to the turbo, or one could.

OTTO & WANKLE ENGINE: Rotary engines perform exceptionally well at high loads and high rpm, as they have less intake restriction by not having intake or exhaust valves. But they perfom poorly otherwise. So how about Mazda build an inline three cylinder engine with a rotary engine taking the place of a fourth cylinder? Then only use the rotary when high power is needed. All the rest of the time, the three cylinders handle the load. In this engine, the three cylinders would need to be spaced at 120 degrees. Since a each rotor in a rotary fires like three cylinders, this engine runs, and is balanced, like six. The cylinders obviously need a separate throttle from the rotor. And it seems just closing the throttle and cutting fuel might be all that is needed to deactivate the rotor.

Considering that the three cylinders could handle the load the vast majority of the time, this engine would run with a high effective expansion ratio. This should make an engine with good power and efficiency. I suspect that lubricating the rotor would still require firing it at least intermittently. Interesting, though! BTW, the rotor could be boosted too for higher power!

Another possibility is adding a non-firing rotor to a three or six cylinder engine where the exhaust from the otto cycle cylinders flow to and through the rotor for an expanded expansion ratio. See next idea.

WANKLE ATKINSON ENGINE: (3-5-2020) The idea is to add a non-firing rotor to a two rotor Wankel engine. Exhaust coming from the convential rotors would then be routed into the non-firing rotor, which could be between the conventional rotors. The non-firing rotor would not have any spark plugs. The non-firing rotor could have intakes and exhaust ports on either side of the housing so that the exhaust coming from one of the conventional rotors would enter one side of the non-firing rotor housing and exit through the other side. Provided the non-firing rotor is larger, which could be done simply by making the non-firing rotor wider, then the overall expansion ratio is expanded. The expansion ratio is then greater than the compression ratio, which makes this engine run an Atkinson cycle.

After some research, it turns out this has been tried with piston engines. It dates back to the 1904 Compound Engine (See: patent #640,890) Better yet, here is a link:It seems that this engine idea with regards to a piston engine running a "simulated" Atkinson cycle, like a Prius, has no advantages. But for a Wankel engine, which has the problem of the leading edge of the rotor rotating away from the flame front which leaves unburned fuel exiting, it would have a large advantage. Advantages would be that the air fuel mixture would have twice as long in the engine to burn, as the burning mixture has to flow through two expansion strokes, as well as the expanded expansion ratio. The downsides are increased friction and weight. Another downside is another rotor to lubricate. But it may be that the advantages outweigh the disadvantages for this idea. I wonder if Mazda has considered this.

Here is a similar idea:

VARIABLE VALVE POSSIBILITIES: (4-9-2020) Infinitely variable and independent valve actuation opens up many really interesting possibilities. Camcon and FreeValve show us this can be done. So I am going to share a few.

First though, variable compression ratio is the obvious combination with fully variable valve control that would make for an ideal engine. There is an interesting alternative though. What I would like to see is a multi-cylinder engine with some cylinders having a higher compression ratio than the others. The higher compression ratio cylinders could run the modified Atkinson cycle when appropriate, and lower compression ratio cylinders could provide more power for higher loads.

So for example, one bank of a “V” engine could be the efficient side, running any combination of late or early intake valve timing, and/or low lift to throttle the maximum amount of intake air. This would enable a high compression ratio of say 13 to 1 or higher.

The other bank would then have a lower compression ratio, and could be boosted through supercharging or turbocharging, or both. Now this seems like you would gain efficiency on one bank only to lose it to the other. But with variable valves doing the throttling, and/or cylinder deactivation, it would be easy to run the vast majority of fuel through the efficient cylinders in normal use.

This idea does not need to be limited to “V” engines. I could imagine a five cylinder with two efficient high compression cylinders. BTW, in a five cylinder, the second time the two efficient cylinders fire, they cancel the vibration pattern started by the fist time the two cylinders fire - it you think about it. You could probably end up with an about 300 hp 2.5-liter engine, if the other three cylinders are turbocharged, with the engine running the majority of fuel through two high efficiency cylinders. I could imagine getting some very good efficiency out of that. Also, Camcon's valves make narrow angle (VR6 style) engines easy, which gives good packaging without any of the negatives usually encountered.

With regard to cycles, fully controlable valves open up a lot of possibilities. I can see six and eight cycle operation, which would be different from the rolling deactivation Camcon disclosed. Instead of completely deactivating a cylinder after a power stroke, one could instead leave at least some of the exhaust in the cylinder during low to medium power operation to be compressed again and expanded once more before exiting to the exhaust. Normally, there is some unburnt fuel that is then taken care of by the catalyst. The higher the RPM, the more there is. If you leave some of the exhaust in the cylinder for another cycle, it will add more power if it burns after the second compression stroke. But if it burns before that, it will add more heat to the engine block. This transfers into the next intake compression cycle to add heat, which quickens the burn under light loads.

This brings us to adding a pre-intake compression stroke, for an eight-stroke engine. If air is brought into the engine during an intake stroke, and then compressed, then expanded in the cylinder, and then compressed a second time, then one would think it would absorb more total heat - as it has more time to do so. That may provide a fast burn from being hotter. Basically, these ideas are replacing deactivation with regeneration, which is a known technique from power plants. (Of course, the eight stroke would probably need at least partial direct injection.)

Also, there are other possible uses of fully variable valves. I could imagine a valve that simply opens up to a closed volume. Open this valve during the compression stroke to compress some intake air into it. Close it before the end of compression and you can lower the effective compression ratio, while the expansion ratio stays the same. You would then open the valve either during the exhaust stroke, or the intake stroke, or between the two, to let the compressed air back out. This is another way to achieve an Atkinson style cycle. If the compressed air is let back out during the intake stroke, it might be more efficient than throttling the intake, as is the usual way Atkinson is done.

Also, a valve could lead to a compressed air tank, which could use the engine for storing braking power to be reused later, which I believe Koenigsegg has already suggested.

Along these lines, your valves could also make the six-cycle idea that injects water into the cylinder in the fifth stroke viable too.

MOLECULAR SIEVES FOR ENGINES: (Posted 4/10/2020) Air comprises aproximately 80% Nitrogen (N2) and 20% Oxygen (O2). So if the percentage of oxygen could be increased in the incoming airflow, then power could be increased. There is a way to do this, at least for boosted engines.

What can be done is to add a molecular sieve to the intake manifold. The material to use is zeolites, as they have holes large enough to allow the nitrogen in the air to be absorbed, while the holes are too large to absorb oxygen. So the pressurized air in a boosted engine would push some of the nitrogen into the pores of the zeolites. This in turn would increase the oxygen percentage in the intake flow that reaches the engine.

It would not take a large increase in percentage. Let's for the sake of example say that a molecular sieve could increase oxygen from 20% to 25% of the incoming air. Well, that doesn't sound like much. But that amount would mean the engine would have 25% more oxygen available, and could make 25% more power, even though only 5% of the intake airflow would be absorbed by the sieve.

The sieve could act as a filter and nitrogen could flow through it to the outside air. Or it could just be an absorber, as full power in modern cars is usually only used for a short amount of time. If the zeolites just absorb, then nitrogen would come back out of it during part throttle operation.

As far as I know, no one has tried this. I am posting this as it is interesting, but modern turbo and/or supercharged engines don't usually need more power. Increasing the percentage of oxygen would likely increase NOX emissions, which could limit this idea.

I'll post more sometime, as there are plenty more that are interesting.

FIGHTING FIRES: (Posted 4/19/2020, updated 9/20/2021) A fire contains all the raw materials needed to put itself out. First, a fire breathes in air and expels exhaust. The fire only uses the oxygen from the air, and the nitrogen passes through. So a fire has two materials that can be used to put out the fire. Those materials are the exhaust gases and the nitrogen (N2) in the incoming airstream.

A fire is also a source of energy. Heat energy from the fire can be used to power a device. There exist methods of turning a fire into work or electrical energy. First, PV panels can turn the radiant energy of the fire into electricity. However, it takes a special kind of PV. A fire puts out most of its energy in the near infrared. There exists cells that work in this region. They are not terribly efficient. But a fire posses more photons per unit area than sunlight, so PV is a distinct possibility. There are some possible problems. One is that smoke from the fire can collect on the PV panel and interfere. Also, PV panels lose efficiency when they heat up. Another method is to use a Stirling engine, which utilizes external combustion. The trick here is how to get a conductive path to the fire, and to a cooler temperature source, which could be the incoming air. One other possibility is thermoelectric devices that use the Seebeck effect.

One idea is that if you can use the energy of the fire, or even an energy source you bring to the fire, you could then use the energy to capture some of the incoming air, then pressurize it and use a molecular sieve to separate the oxygen from the nitrogen in the air. What would be done with the oxygen is to route it up to the sky. What is done with the nitrogen is to the route it to the fire suffocating the fire.

I think the best way would be to collect nitrogen into a tank, wait until a good amount is collected, and then to hit the fire with a blast of nitrogen all at once. I don't think you can make nitrogen fast enough through the molecular sieve to have a steady flow through device. By the way, these molecular sieves exist. Zeolites are molecular sieves that are commonly used in commercial PSA based portable oxygen supply devices. In the case of putting out fire, what you want is the nitrogen, and not the oxygen, but the process is the same proven process.

Another idea is to just route the exhaust back to the fire. In these ways the oxygen to the fire is diluted and the fire is suppressed.

This is at the basic idea stage - feedback welcome.